Modular space snack manufacturing | Invent Your Own Challenge

Team Updates

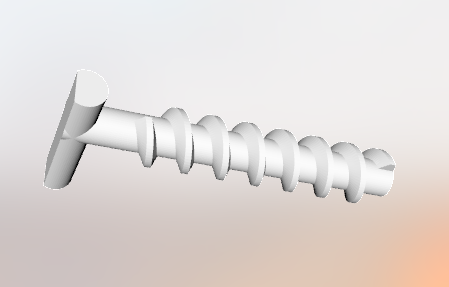

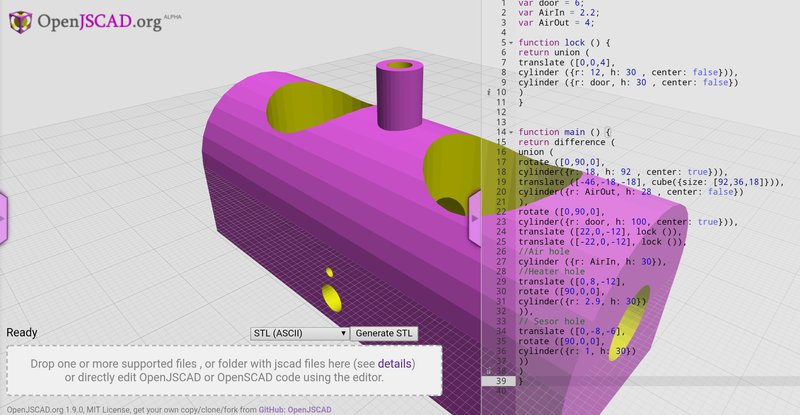

var door = 6;

var AirIn = 2.2;

var AirOut = 4;

function lock () {

return union (

translate ([0,0,4],

cylinder ({r: 12, h: 30 , center: false})),

cylinder ({r: door, h: 30 , center: false})

)

}

function main () {

return difference (

union (

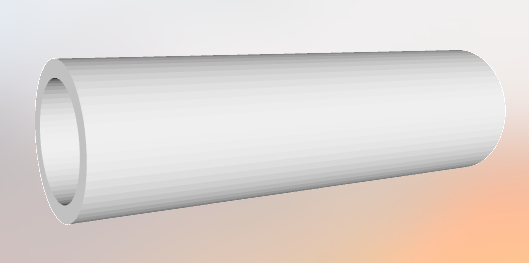

rotate ([0,90,0],

cylinder({r: 18, h: 92 , center: true})),

translate ([-46,-18,-18], cube({size: [92,36,18]})),

cylinder({r: AirOut, h: 28 , center: false})

),

rotate ([0,90,0],

cylinder({r: door, h: 100, center: true})),

translate ([22,0,-12], lock ()),

translate ([-22,0,-12], lock ()),

//Air hole

cylinder ({r: AirIn, h: 30}),

//Heater hole

translate ([0,8,-12],

rotate ([90,0,0],

cylinder({r: 2.9, h: 30})

)),

// Sesor hole

translate ([0,-8,-6],

rotate ([90,0,0],

cylinder({r: 1, h: 30})

))

)

}

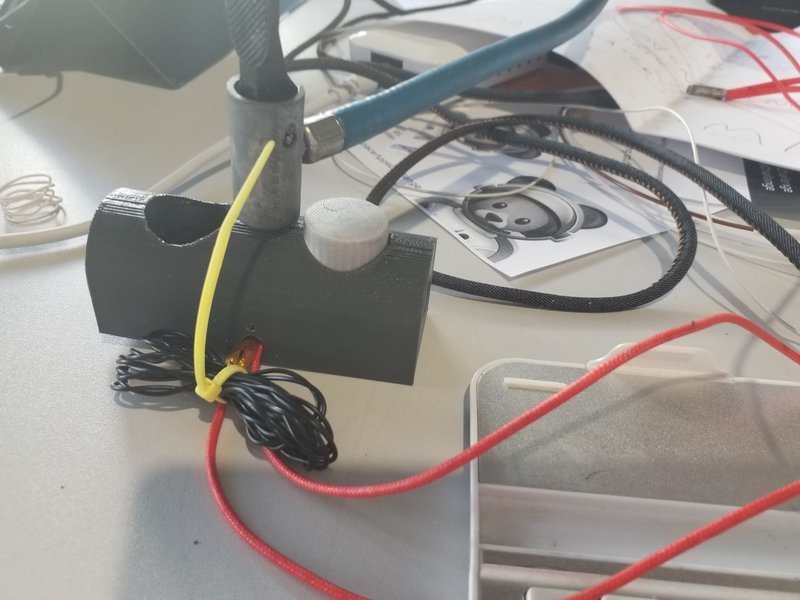

We have some heat resistant 3D printer filament, donated by 3dk.berlin, that can handel the pressure and heat needed to cook and puff grains of wheat.

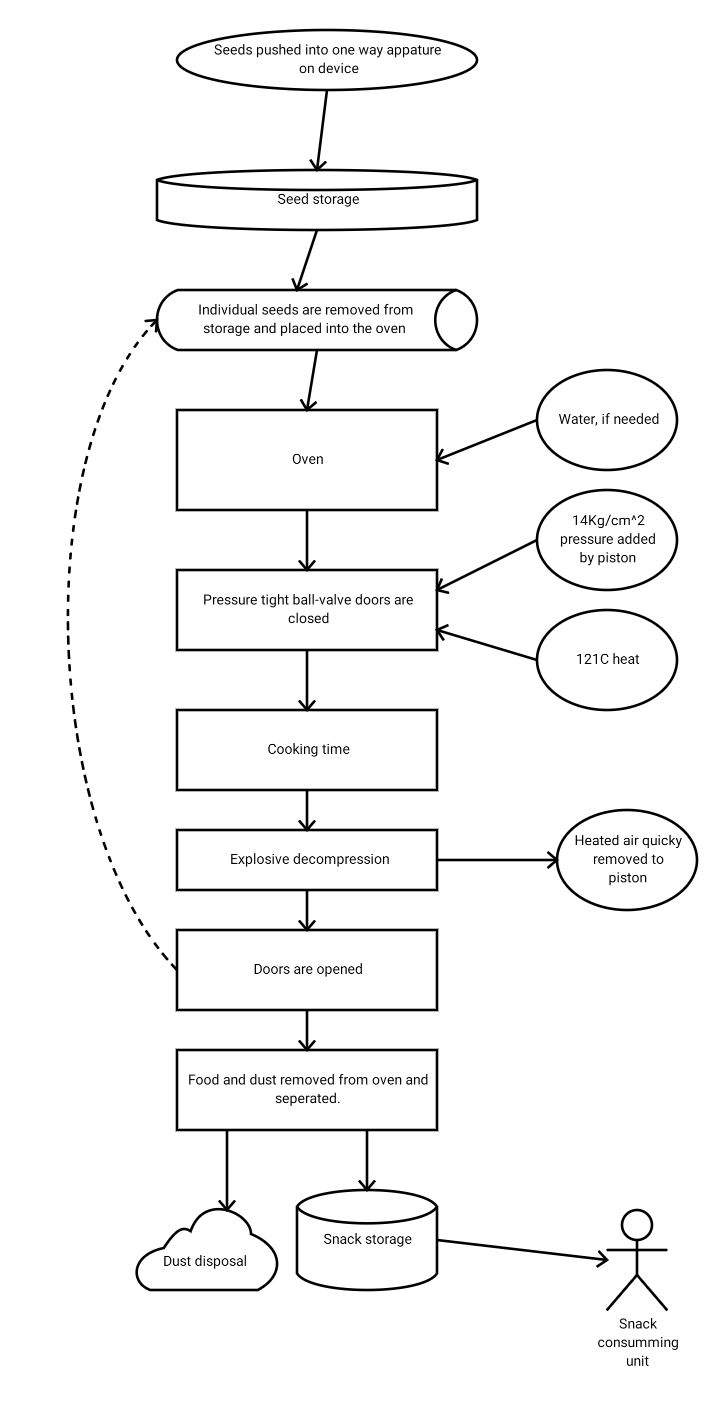

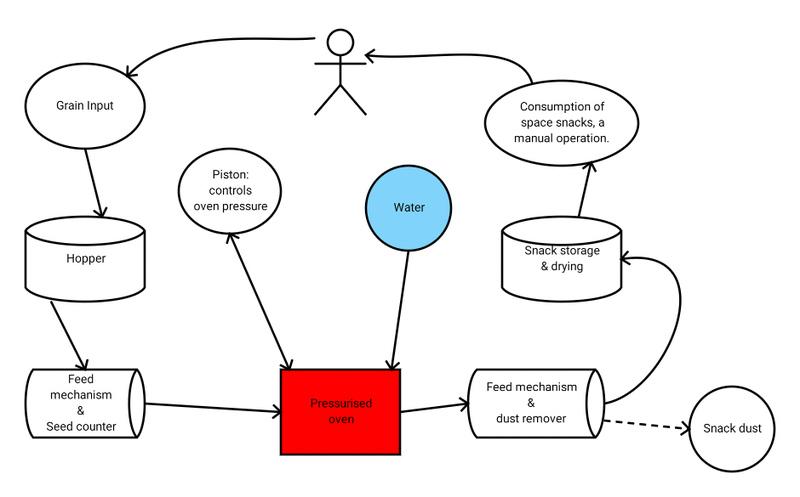

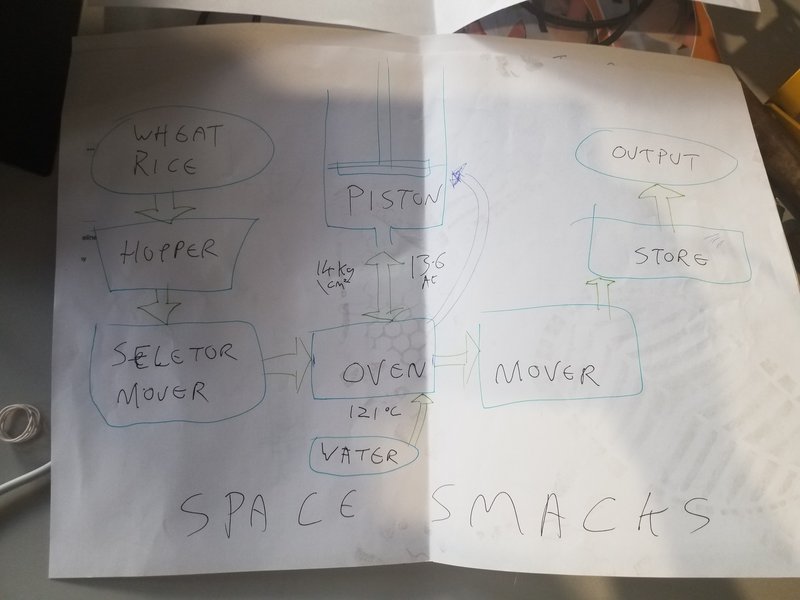

The chamber has a heating element and two pressure doors. The pressure is provided by a bike pump, our plan is that nitrogen disolves into the grains during cooking and explosive decompression at the end of the cooking process causes the grains to puff into Smacks.

To do:

Make 3D printed doors that can hold 14kg/cm^2

Test if explosive decompression can be used in place of milling of grains before cooking.

SpaceApps is a NASA incubator innovation program.