Interstellar Dolphin | Make Sense Out of Mars

Awards & Nominations

Interstellar Dolphin has received the following awards and nominations. Way to go!

The Challenge | Make Sense Out of Mars

System for manufacturing Human Body Immobilizers

The different injures on the Mars can be very big problem for future martians. We are developing portable small 3D scanner that can help produce different custom immobilizers for martians.

INTRODUCTION

It is known that the weightlessness has temporary and long-term effects on the human body. There are several investigations in this area [1, 2]. The effects are: absence of the sense of up and down, downdisruption in the proprioceptive system, the bones weaken, so astronauts are more susceptible to breaking them if they slip and fall, just like people with osteoporosis. Also muscles lose mass.

MARTIANS ON MARS

It is can be expected that the Martians will also be affected by low gravity because the gravity of Mars is three times less than the gravity of the Earth. So injuries during future exploration of the Mars will be a great problem. On the Earth during the treatment of fractures it is used gypsum. But there is no gypsum on the Mars and water will be very expensive.

The solution may be found in field of 3D scanning and 3D printing. Since 2015, NASA has been holding a competition on design of 3D printed habitats for martians [3]. They can be printed from materials gathered from the surface of the Red Planet, including basalt and renewable bioplastic [4].

These technologies can be used not only for buliding houses but also for creating different useful things. Also the following tecnologies can be used in medicine especially in traumatology. 3D printed immobilizer can be considered as a solution for the problem of the future Martian exploration issues.

WHAT WE DESIGN

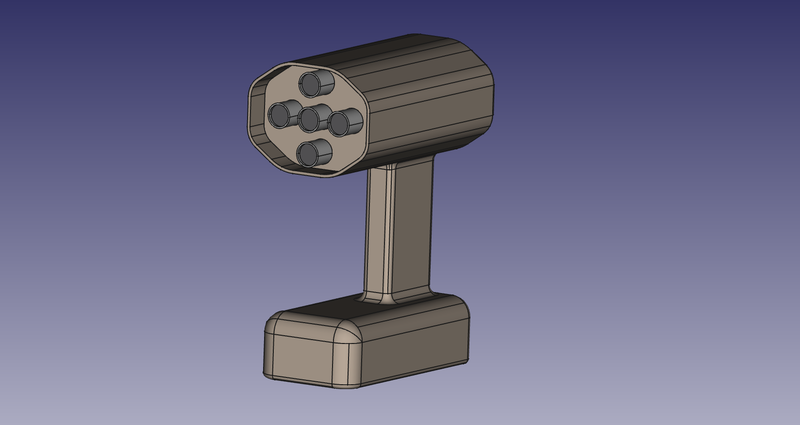

For 3D scanning we propose to use portable 3D scanner. In our project we decided to use ultrasonic type of sensors. The advantages of the following sensors is cheapness, low power consumption, unpretentiousness and they widely used in robotics.

If we want that the 3D scanner will be portable we need to accurately determine the position and direction on the scanned object. There is no GPS or other navigation system on Mars, and our device will be used inside medical units in which there is no visibility of stars. For determination of positions and directions we propose to use the on-board inertial navigational system.

So our 3D Scanner consists of two sets of sensors. One is the set of ultrasonic sensors and other one is set of MEMS gyroscopes and accelerometers [5, 6, 7].

Also for collecting and transferring data we choose to use Arduino. All data are transferred to PC microcomputer for reconstruction of scanner trajectory and point cloud. Using collected point cloud the surface of the body is reconstructed. Based on that surface the model of immobilizer is built.

The density of gypsum and basalt are close. So printed immobilizer may be lighter that one on the Earth, Also shape of immobilizers can be designed in different ways. For example it can be built based on the triangulation of surface of body.

We developed C code for Arduino that collects data from sensors and transmits them to Python script through Serial port.

CHALLENGES FACED AND RESEARCH

First challenge is the precision of inertial navigation system. For increasing the precision we choose to use 4 sensors that will be placed on non-orthogonal planes [6].

Second one is the precision of ultrasonic senor due to different effects in the propagation and reflection of ultrasound. We tried to increase accuracy of the ultrasonic sensors in several ways the one way is to compensate movement of 3D scanner using four ultrasonic receivers arranged as cross. Transmitter placed in the center. Such arrangement of sensors can compensate the movement of 3D scanner with the help of evaluation of differences of time among receivers. Second way was that we tried to make beam of ultrasonic ray narrower. We did some basic research in sound propagation and analyze some papers [8, 9, 10] and we investigate the influence of different horns on accuracy of ultrasonic sensors.

Third one is organization of communication between Arduinos for fast measurements and data exchange. In system where we need measure position and distance precise it is needed to use a few Arduinos. One is measure position one is for collecting and transferring data other are for measure of distance. If we measure distance with the help of ultrasonic sensor we have to wait sound propagation, but the position of the scanner should be determined much more often. That's why we need to use a lot of Arduinos.

HOW WE SEE IT IN THE FUTURE

The idea of this 3D scanner is realizable. It can be used for scanning of injured people now in the Earth. There are several projects now that consider the printing of immobilizers with the plastic. But the cost of 3D scanning is too high now. The use of cheap ultrasonic sensors can reduce the cost of 3D scanning in medical purposes.

SOURCES

- https://www.space.com/39952-nasa-twin-study-spacef...

- https://www.space.com/23017-weightlessness.html

- https://www.cnet.com/news/nasa-picks-3d-printed-houses-we-could-use-on-mars/

- https://thespaces.com/ai-space-factory-designs-homes-for-planet-mars/

- http://earchive.tpu.ru/bitstream/11683/45802/1/reprint-nw-20198.pdf

- playground.arduino.cc

- https://github.com/PranaliDesai/Multiple-Ultrasonic-Sensor-

- https://www.diva-portal.org/smash/get/diva2:174299...

- http://citeseerx.ist.psu.edu/viewdoc/download?doi=...

- https://www.grc.com/acoustics/an-introduction-to-h...

HARDWARE

- Arduino Uno (2 pieces),

- Ultrasonic sensors HC-SR04 (4 pieces),

- Accelerometer and gyroscope GY-521 (4 pieces).

SOFTWARE

- Python

- FreeCAD

- QCad

- Blender

- Fritzing

- GNU Octave

OUR TEAM

- Mirnyi Serhii (team leader, 3D design, programming, electrical parts)

- Arseniuk Mykhailo (electrical parts)

- Kirill Blagodarov (3D design)

OUR GITHUB

SpaceApps is a NASA incubator innovation program.